RESEARCH & DEVELOPMENT

It is certainly in research and development that our collaboration and partnership with the customer reaches its peak. To find the best solutions to our customers’ requests, we collaborate with the best universities and with various research studies to ensure the maximum innovation in terms of both materials and processes for the production of our precious components for top of the range watches.

PALLADIUM

Journey to the roots of an alloy

The first of our “tools of the trade” is the crucible; once a project has been defined, the commitment to satisfy our Customer starts from the casting.

For this reason, in collaboration with the Industrial Engineering Department of Padua University, we have invested in research into new alloys and, in particular, white gold alloys.

We varied the working temperature of the pre-alloys and of the alloys and the metals of which they are composed. After that, we analysed the results in specialised laboratories with optical microscopes, scanning electron microscopes (SEM), microdurometers and colorimeters, assessing the quality of the nucleation, the growth, the hardness and the colour.

We thus obtained an alloy that enabled us to avoid the so-called “orange peel” effect and that offered us the important possibility of collaborating in the editing of three graduation theses on white gold alloys for jewellery.

BETWEEN SUSTAINABILITY AND TECHNIQUE

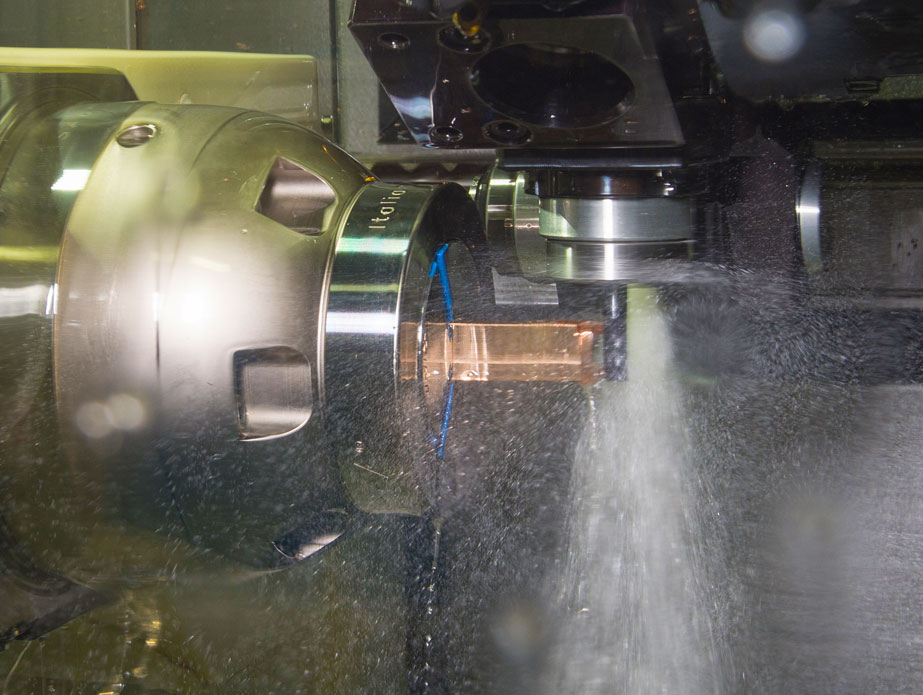

The management of grinding oil for machine tools

At Salin, innovation is not shut up in an office, but is free to run through all the departments, involving collaborators in a continuous search for improvements, according to the Juran quality trilogy approach.

Thanks to this approach it has been possible, for example, to improve one of the most efficient machine tools at our disposal, which is used for processing steel and gold.

In collaboration with the operators of the machine tools for precision working, we have conceived and made an innovative device for managing grinding oil that the machine tool manufacturers had not thought of.

Thanks to this device, we have recovered precious metal, prevented the steel cells mixed with the oil from affecting the working of the gold, and improved the disposal of the used oil, at sustainability level.

A 100% Veneto approach: inventiveness, tenacity, the passion for mechanics and the use of instruments originally created for edible oil.

FLEXIBILITY AND VISION

An excellent approach is a global approach

To excel means to “push oneself farther”, to go beyond limits and boundaries. In our search for excellence we seek solutions even outside our own area of responsibility.

When a customer asked us to reduce the thickness of the gold of a watch case, we reworked the technical drawing, checking its feasibility and the aesthetic and structural aspects.

But it is not just a question of solving problems: they must be anticipated with an all-round approach. We went beyond the customer’s request and fortunately checked with the Swiss Customs Office concerning the possibility of punching the requested purity.

Having found that it was impossible, we made a third design that enabled us to receive the order and the Customer’s thanks.