PRODUCTION

Our production: a complete cycle under the banner of quality

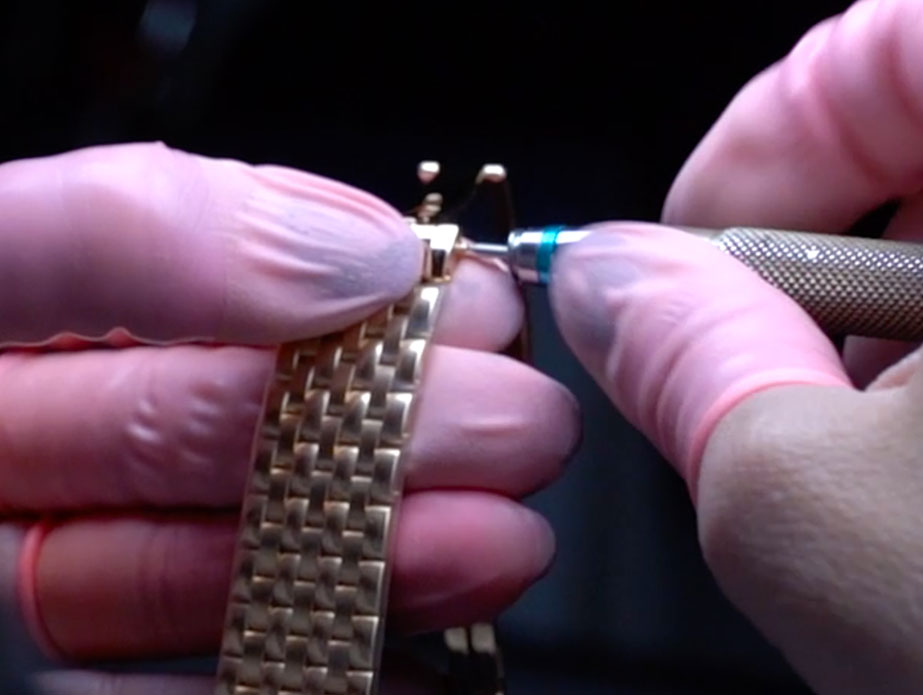

QUALITY CONTROL

Certifying quality with continuous controls

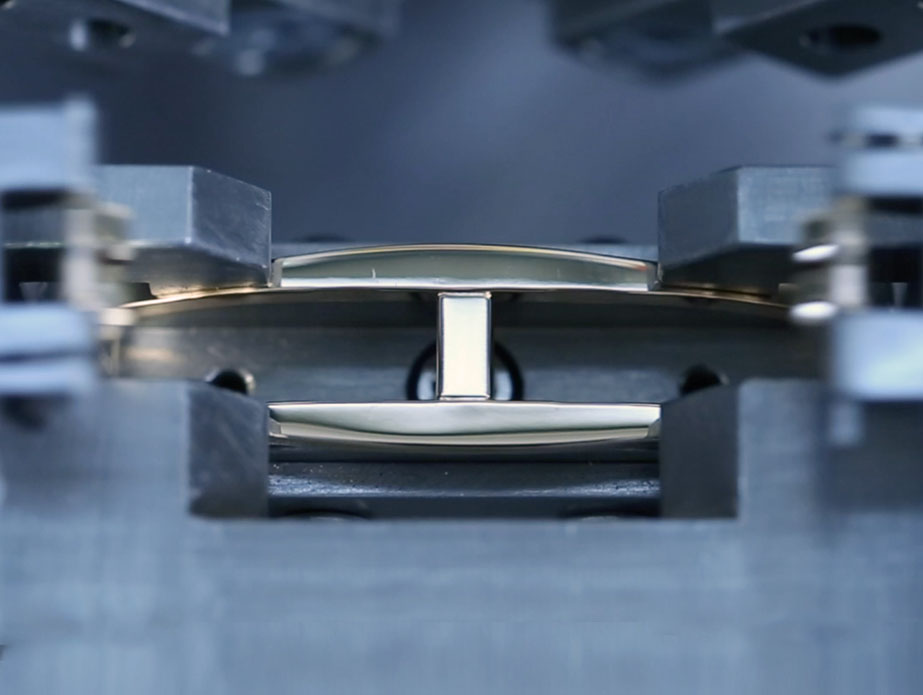

Thanks to detailed tests, we check the durability and tightness of the components on a sample basis; every single closure is subjected to a snap test. But quality doesn’t just come at the end: to guarantee the perfect result, we monitor every step in the production process.